The method behind successful projects by a trusted Aluminum Casting Company

The Development of Light Weight Aluminum Spreading Techniques

Over the decades, various ingenious methods have actually changed light weight aluminum casting, significantly improving its performance and accuracy. The evolution began with standard sand casting methods, which, while reliable, frequently led to inconsistencies in surface finish and dimensional accuracy. The introduction of die casting in the mid-20th century allowed for faster production rates and improved high quality, as molten aluminum was pushed into mold and mildews under high stress, lowering porosity and boosting information.

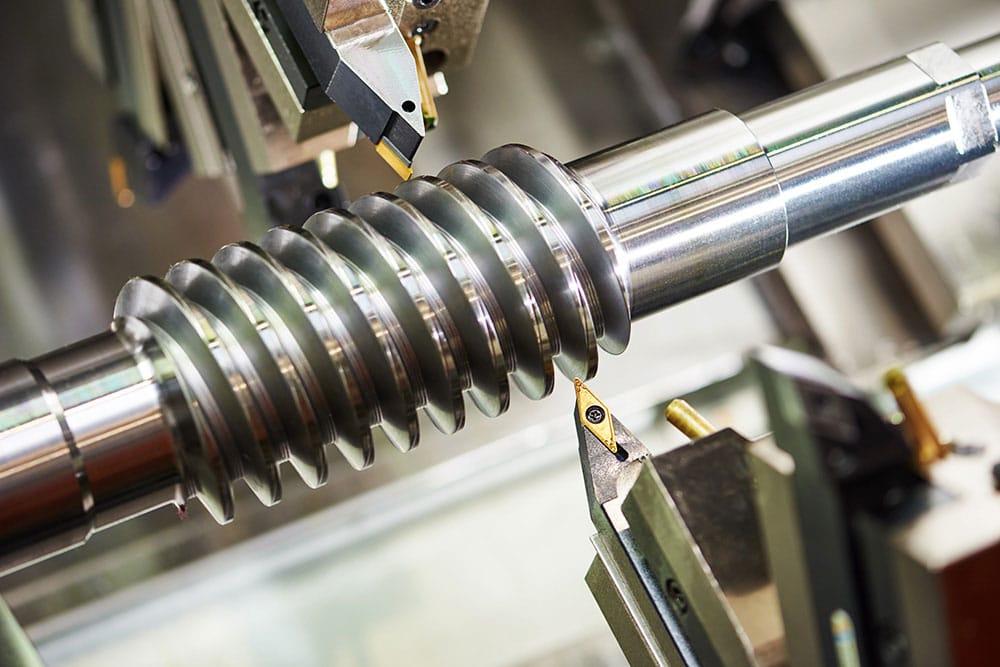

More innovations consisted of investment casting, which offered even intricate designs and finer resistances. The emergence of computer numerical control (CNC) technology also revolutionized mold and mildew layout, making it possible for makers to produce complicated geometries with impressive precision. Today, additive production methods, such as 3D printing for producing molds, get on the increase, enabling rapid prototyping and reduced preparations. Overall, these advancements have actually considerably affected the aluminum spreading process, catering to a wider range of commercial applications.

Benefits of Light Weight Aluminum in Manufacturing

Light weight aluminum has come to be a recommended product in production as a result of its special combination of residential properties that enhance efficiency and efficiency throughout numerous applications. Its light-weight nature enables lowered energy usage during transportation and setting up, making it an economical choice for lots of markets. Additionally, aluminum shows outstanding deterioration resistance, guaranteeing long life and reducing maintenance prices.

ght proportion allows the manufacturing of durable yet light-weight components, which is specifically advantageous in fields such as automobile and aerospace. Light weight aluminum also provides superb thermal and electrical conductivity, making it suitable for a range of commercial applications, consisting of electronics and heat exchangers.

Moreover, light weight aluminum's pliability permits intricate layouts and simple construction, promoting the production of complex forms without jeopardizing architectural honesty (Aluminum Casting Company). These advantages collectively add to aluminum's growing importance in modern-day production processes, driving advancement and improving product performance across a variety of industries

Advancements in Light Weight Aluminum Casting Innovation

As improvements in producing modern technology remain to advance, technologies in light weight aluminum spreading have emerged, enhancing efficiency and accuracy in manufacturing processes. Among these technologies is the intro of sophisticated simulation software application, which enables producers to model the spreading process virtually. This technology makes it possible for the forecast of potential defects and maximizes mold layout, eventually decreasing material waste. In addition, the growth of brand-new alloys has expanded the series of applications for light weight aluminum castings, boosting mechanical properties and rust resistance.

Furthermore, the fostering of 3D printing for mold and mildew manufacturing has actually changed the casting procedure, enabling the production of intricate geometries that were formerly unattainable. This shift not just shortens preparations but likewise helps with modification in manufacturing. Generally, these innovations add greatly to the quality and adaptability of aluminum spreadings, positioning them as a vital part in the future of manufacturing innovation.

Influence On Manufacturing Efficiency and Expense Reduction

While the innovation of light weight aluminum casting innovations presents countless advantages, its most notable effect hinges on improving manufacturing performance and driving price decrease. By streamlining the casting process, producers can create complicated elements with higher rate and accuracy, substantially decreasing waste. Technologies such as high-pressure die spreading and progressed mold styles enable quicker cycle times and boosted dimensional accuracy, which minimize rework and scrap prices.

Additionally, the light-weight nature of light weight aluminum adds to reduce transportation costs and energy consumption during production. Consequently, manufacturers can achieve substantial economies of scale, inevitably decreasing the per-unit expense of products. The ability to generate high-quality castings in bigger amounts likewise enables firms to react more swiftly to market needs - Precision aluminum casting. These performance gains and cost financial savings setting aluminum spreading as a competitive advantage in the manufacturing landscape, fostering further financial investments in modern technology and capability growth

Applications of Light Weight Aluminum Casting Throughout Industries

The adaptability of aluminum spreading has brought about its extensive fostering across numerous sectors, exploiting on the advantages of light-weight, resilient parts. In the vehicle sector, light weight aluminum spreadings are made use of for engine blocks, transmission housings, and wheels, contributing to sustain performance and efficiency. The aerospace market utilizes aluminum castings for structural parts, where weight decrease is necessary for trip efficiency. In addition, the consumer electronic devices field leverages aluminum casting for gadget housings and components, boosting durability while preserving a streamlined layout. The building sector additionally gains from aluminum castings, using them in home window structures and architectural elements that need both toughness and visual appeal. Additionally, the medical field uses light weight aluminum castings for equipment and gadgets, where accuracy and integrity are paramount. Overall, the varied applications of light weight aluminum spreading across these industries demonstrate its essential duty in progressing contemporary manufacturing practices.

The Future of Light Weight Aluminum Spreading in Production

Advancement in aluminum casting innovation assures to Precision aluminum casting reshape producing procedures in the coming years. Developments such as 3D printing and computer-aided design are improving manufacturing, enabling much more complicated geometries and lowered waste. The combination of automation and robotics boosts performance, enabling manufacturers to produce premium elements with very little human treatment. Furthermore, the advancement of brand-new aluminum alloys boosts toughness and longevity, increasing the prospective applications in sectors like aerospace and auto.

As sustainability ends up being a priority, reusing abilities within aluminum spreading will boost, decreasing ecological impact. The execution of wise production methods, including IoT and information analytics, will additionally optimize manufacturing workflows and upkeep practices. These advancements not just enhance operational efficiency yet additionally lower costs, making light weight aluminum casting a a lot more attractive option for suppliers. Eventually, the future of aluminum spreading holds guarantee for technology, sustainability, and enhanced competitiveness in the global market.

Regularly Asked Concerns

What Security Actions Are Associated With Aluminum Spreading Processes?

Safety measures in light weight aluminum casting procedures include protective gear, appropriate air flow, training on equipment use, normal maintenance of machinery, monitoring of molten metal temperature levels, and adherence to safety and security procedures to avoid accidents and assurance worker health.

How Is Aluminum Spreading Environmentally Lasting?

Light weight aluminum casting is ecologically lasting due to its recyclability, energy effectiveness, and lowered greenhouse gas emissions. Using recycled light weight aluminum greatly reduces the power required for production, lessening ecological impact while conserving natural deposits.

What Are Usual Defects in Aluminum Castings?

Common flaws in light weight aluminum spreadings consist of porosity, shrinkage, misruns, cool shuts, and inclusions. These problems can arise from incorrect temperature level control, inadequate mold layout, or contamination, affecting the total quality and stability of the end product.

Can Aluminum Casting Be Recycled?

Yes, aluminum casting can be recycled. The reusing procedure reduces energy intake and ecological influence, enabling the reuse of light weight aluminum in new items. This sustainability element improves its appeal in various production industries.

What Industries Primarily Use Aluminum Spreading?

Light weight aluminum spreading is mostly made use of in the auto, aerospace, durable goods, and electronic devices industries. These markets take advantage of aluminum's light-weight, corrosion-resistant homes, improving product efficiency, performance, and longevity throughout different applications and parts.

Over the decades, numerous ingenious methods have changed aluminum spreading, significantly improving its efficiency and precision. As advancements in producing technology continue to evolve, innovations in aluminum casting have actually arised, boosting effectiveness and accuracy in production processes. While the development of aluminum spreading modern technologies presents many benefits, its most noteworthy impact lies in improving manufacturing effectiveness and driving expense decrease. The aerospace sector uses aluminum spreadings for structural elements, where weight decrease is crucial for trip efficiency. Light weight aluminum casting is ecologically lasting due to its recyclability, energy performance, and decreased greenhouse gas exhausts.